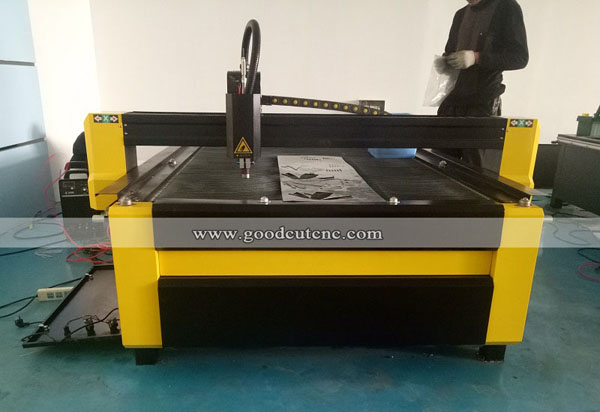

GC1325P 2023 Best 4x8 CNC Plasma Cutter Table for Sale at Affordable Price

Feature :

10. It can cut metal plate of advertising 3D lighting letter and flute profile letter with high cutting precision.(USA power is optional)

Parameters :

Model | GC1325P |

Working Size | 1300mm*2500mm |

Repeat Positioning Accuracy | ±0.05mm |

Traveling Speed | 0-24000rpm/min |

Cutting Speed | 10-15m/min |

Transmission model | Gear rack drive |

Transmission system | X,Y Taiwan Hiwin high-precision, zero clearance increased linear guide+ rack |

Operating System | START or DSP with USB Interface |

Driver | Leadshine drives |

Plasma Power Supply | Huayuan/Hypertherm |

Cutting Thickness | 0.1-30mm |

Cutting Type | Plasma/oxy-acetylene or propane |

Input Voltage | 3 phase,220v/380v±10% |

Mode of File Transfer | USB Interface |

Guide Way | Imported square rail |

Table-board | Steel blade saw tooth mesa |

Straight Line Positioning Precision | ±0.2mm/10m |

Straight line Repeat Precision | ±0.3mm/10m |

Environmental Temperature | -5~45°C |

Humidity | <90% No concreting |

Parts display

China Huayuan plasma source

Heavy duty structure, keep machine working stable.

1. English manual and videofor machine using and maintaining,explaining the operation steps in detail;

2. Professional after-sales service staffs, providing 24-hour online service;

3. Provide free technical training and factory field operation teaching

Aplications :

1.The Suitable material:

Cutting or Engraving on Iron Plate, Aluminum sheet, Galvanized Sheet, Stainless,Titanium plates etc.

Cars, motorcycles, pressure vessels, chemical machinery, nuclear industry, general machinery, engineering machinery, steel structure, shipbuilding and other industries.

What Is A Plasma Cutter?

This cutting device is a type of thermal metal cutting tool that uses high velocity plasma or ionized gas to cut through metal, and blow away the molten metal with high-speed airflow at the same time to form a narrow plasma cut seams. It is used to cut various metals, like carbon steel, stainless steel, copper, aluminum, cast iron, and more. It makes it possible to cut through electrically conductive metals with precision. It features with high cutting speed, thin cut seams, low deformation, small heat-affected zone, easy-to-use, and energy saving. With the pilot arc, it will generate a low power plasma arc in the air, which make the cut with lower cost.

It is used for sheet metal fabrication, metal structure making, machinery building, repair shop, drilling, digging, beveling, patching and more metal cut projects & plans.

What Is A CNC Plasma Cutter?

The term CNC stands for Computer Numerical Control. That is a CNC cutter will cut through metal using ionized gas with computerized command.

A CNC plasma cutter is a type of computer numerical controlled automatic cutting system that uses ionized gas torch to cut metals into different profiles and shapes with CNC controller, including mild steel, stainless steel, carbon steel, galvanized steel, hot rolled steel, cold rolled steel, iron, brass, copper, alloy, aluminum, bronze, and titanium.

A CNC cutter kit is composed of machine frame, controller, power supply, gas torch, blade or sawtooth table, driver, motor, control system, software, guide rail, ball screw, optional parts and consumable parts.

Some of the synonyms of a plasma cutter are cutting torch, arc cutter, cutting machine, arc welding cutter, cutting system, plasma table, metal cutter, cutting tool, arc welding machine, or plasma cutting device.

What Is A CNC Plasma Table?

It is a type of automatic cutting machine with custom welding table top, which can be well adapted to cut metal projects with different sizes. The CNC controller will make it with a high degree of manufacturing flexibility, high accuracy, stable quality, high productivity, easy to improve working conditions, and are conducive to modernization of production management. Such a tool is a combination of a cutter and controller, which can give play to the greater advantages of gas cutting. In order to realize automatic machining, it must be capable of continuous feeding and automatic feeding, and the torch must be able to move separately or in combination in the horizontal and vertical directions to form the required curve. The various functional parts of the machine must be able to closely cooperate and coordinate to achieve precise continuous cutting. At the same time, various technical parameters can be flexibly adjusted and optimized to meet the cutting requirements of different metals.

How Does A CNC Plasma Cutter Work?

Plasma cutting is a thermal machining method that uses the heat of a high-temperature ionized gas arc to melt at a metal workpiece, and to eliminate the molten metal by high-speed momentum to create a slit. They send an electric arc by using gas like oxygen, nitrogen or compressed air. This turns the gas to plasma, as well as it promptly blasts through metal to cut it with broadband. A flame cutting torch works by adding a blast of oxygen to the flame which oxidizes the metal and turns it into slag. The torch moves along a tool path with height control directed by a computer. The CNC implies that a computer is used to control the motion supported G-code in a program. Compared to handheld devices, plasma CNC cutters realize automatic machining with X, Y, and Z axis.

What Are Plasma CNC Cutters Used For?

These machines are used for cutting sheet metals, square and round metal tubes, including iron, cold rolled steel, hot rolled steel, stainless steel, galvanized steel, carbon steel, copper, brass, alloy, bronze, aluminum, titanium. They are used for machine tool manufacturing, petro-chemical equipment, light-industrial machinery, pressure vessel, shipbuilding, mining machinery, electric power, bridge construction, aerospace, and steel structure. They are used in hobbyists, home shop, home business, small shop, small business, school education, and industrial manufacturing.

What Are The Types of Plasma Cutters?

The most common types of plasma cutters include the handheld and CNC variant (hobby types and industrial types). The most common power supplies include Huayuan power supply and Hypertherm power supply. According to the working methods, the kits can be divided into air kits, dry kits, semi-dry kits and underwater kits. According to the cutting quality and precision, you will meet the types of ordinary, fine, laser-like, and so on. According to the appearances, the three types are listed bellow:

Portable CNC Kits

The machine is portable, easy to setup, compact in structure, small in space and low in manufacturing cost. However, due to the limitation of the cantilever structure, the stress conditions are poor, the transverse deformation is prone to occur, the transverse cutting width is limited, and the rigidity is poor during high-speed machining.

Gantry CNC Kits

The gantry-type supporting method is bidirectionally supported, the force is more uniform, the equipment has good rigidity, and can achieve a large lateral span, usually up to 3 to 10m. However, the equipment installation requirements are high, the structure is relatively large, and it takes up more plant area. The driving mode is divided into unilateral driving and bilateral driving. Unilateral drive and bilateral drive each have their own characteristics and applications. The unilateral drive avoids the high-precision synchronous control and complicated structure of the bilateral drive. However, due to the offset of the center of mass and the driving force does not pass through the center of mass, asymmetric inertial force will be generated during operation, which is prone to vibration, deformation and tilt. Therefore, it can only be used in a small span. The double-sided drive structure is relatively complicated and requires high-precision synchronous control on both sides, which can be used for a larger span and more stable movement.

CNC Table Kits

The cutting part and the machine are integrated, which is convenient to move in place, but the movement range of the cutting torch is relatively small, and the cutting width is subject to certain restrictions.

How Many Types of CNC Plasma Tables?

The most common types of CNC plasma cutting tables include 4x4, 4x8, 5x10 and 6x12 in feet, some user may call the series CNC tables as 48" x 48" types, 48" x 96" types, 60" x 120" types in inches, some user may call the table kits as 1212 types, 1325 types, 1530 types, 2040 types in millimeter (mm).

What Are The Advantages of Plasma Cutting?

It is an efficient metal cutting method for sheet metal and metal tubes, which has made it to be widely used in many different industries.

You can get benefits from 10 best advantages with fast cuts, ease of use, lower cost, safe to use, multi-tasking, expanded versatility, wide range of material and thickness, eliminated plate warping, raised inside piercing speed, and diminished dross.

Compared with traditional manual & semi-automatic metal cutter, automatic computer-controlled metal cutting system is an integration of quality improvement and cost-efficiency. CNC metal cutters include computerized numerically controlled plasma, flame, water plasma and laser cutting machine. It performs automatic, full-time, high-quality, high-utilization and efficient cutting according to the CNC nesting software.

In industrial production, metal thermal cutting generally includes gas, plasma, and laser cutting. Compared with gas cut, plasma cut has a wider cutting range and higher efficiency. The fine plasma cut system is close to the quality of laser system, but the cost is much lower than that of laser.

It has shown great advantages in saving materials and improving labor productivity. This has promoted it from manual or semi-automatic to numerical control, and has become one of the main directions of the development of numerical control cutting technology.

1. It can cut thicker metals, such as stainless steel, aluminum and its alloys, copper and its alloys, cast iron and other metal materials. You can also use cutting torch to cut insulating materials and non-metallic materials with thickness of more than 150mm.

2. The speed is fast, and the production efficiency is high, especially when working with thin metals with high power, the production efficiency is improved more significantly.

3. The cutting quality is high, the slit is smooth and flat, the incision is narrow, and the heat-affected zone and deformation are smaller than other tools.

4. Low cost, due to the high speed, the use of cheap gas such as nitrogen requires less raw materials and labor than other methods to cut the same material.